How did Festo developed device-agnostic immersive training?

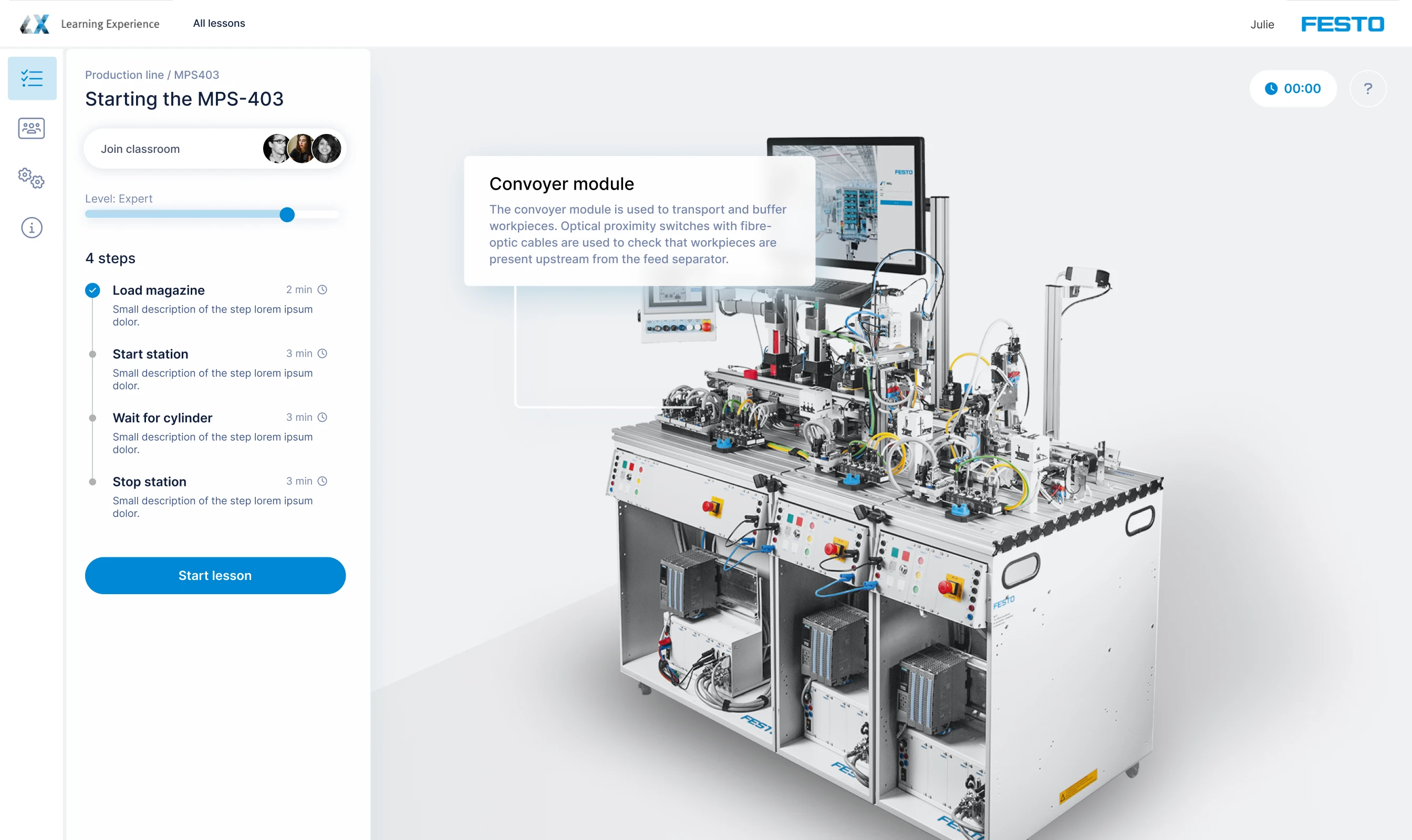

A browser-based, data-driven twin of the MPS 403 delivers immersive training, and multi-user sessions — without installing software.

Sector

Manufacturing

Country

France

Use case

Immersive training & digital twin ops

4–8 weeks

to first pilot

7 × lower cost

to deliver training

3–5 × faster

content updates

25–40% faster

time-to-competency through guided simulation and fault rehearsal*

Rethinking Industrial Training

In industrial training, the classroom hasn’t changed much in decades. Physical machines, static manuals, and scheduled sessions remain the norm.

But these traditional setups come with real limitations:

Every piece of hardware costs thousands to replicate.

Each session depends on machine availability.

And many fault scenarios are too risky—or simply impossible—to reproduce safely.

Festo, a global leader in automation and industrial education, saw a clear opportunity: What if industrial training could become as flexible, interactive, and connected as the smart factories it prepares people for?

That question set the foundation for a proof of concept (POC) built on 3dverse. The goal wasn’t just to digitize training. It was to prove that immersive, data-driven experiences could deliver the same precision and realism as physical machines—at a fraction of the cost and time.

The Vision Behind the Proof of Concept

Festo’s objective was clear:

create an immersive, browser-based experience that mirrors the company’s physical training system, the MPS 403, and demonstrate that real learning outcomes—hands-on, procedural, and collaborative—could happen entirely online. With its digital twin, Festo opened a new era of industrial education: an immersive virtual replica that allows users to explore, program, test, and diagnose a production line without any physical constraints.

The POC aimed to validate key questions:

Can a digital twin simulate physical machine behavior accurately enough for industrial training?

Can multiple trainees collaborate live in one shared 3D space from any device?

Can this be done without installing software or managing heavy local infrastructure?

The answer to all three was yes.

Festo’s engineering and training teams worked with 3dverse to build a browser-based, data-driven digital twin of the MPS 403 system.

The environment was designed to look, behave, and respond just like the real machine—but entirely in the cloud.

What the POC Delivered

1:1 Digital Replica

The MPS 403was recreated in precise, high-fidelity 3D, maintaining the spatial accuracy required for industrial learning.Virtual Control Interface

A live, functional control panel simulated the actual machine interface—allowing trainees to interact with buttons, switches, and sensors as they would in person.Interactive Guidance

Training steps were embedded directly within the 3D scene, transforming static documentation into real-time, context-aware instruction.Real-Time Collaboration

Multiple participants joined the same digital twin simultaneously—whether from a desktop, VR headset, or AR device—without installing software or plugins.

Why It Matters

This proof of concept redefines what “hands-on learning” means in the era of Industry 4.0. Accessible from anywhere, the virtual MPS 403 combines industrial realism with the power of digital learning—supporting universities, training centers, and enterprises in building the advanced skills required for the factories of tomorrow.

It proves that industrial knowledge can scale globally—without duplicating hardware, managing complex IT infrastructure, or compromising on safety and interactivity. For universities and training centers, the model offers new flexibility: no longer must every classroom own a physical MPS 403 unit.

Instead, instructors and students can access an identical virtual version through a secure browser session, experiencing the same procedures, same interface, and same logic—without geographic or logistical barriers.

While still a proof of concept, it has opened a clear pathway toward the future of industrial education:

a world where learning happens in real time, data drives every scenario, and anyone, anywhere, can train on the world’s most advanced machines—with nothing more than a web browser.