How do educators prototype immersive learning without heavy infrastructure?

To test the feasibility and effectiveness of digitizing practical work instructions, initially in Word format, for integration into an immersive 3D environment to improve learning and training.

Sector

Manufacturing

Country

France

Use case

Immersive training

Pignat and 3dverse: Building the Future of Immersive Technical Training

Accelerating Digital Transformation in Industrial Education

In the world of industrial education, Pignat has long stood as a reference in process engineering training equipment — building physical systems that teach generations of students how to operate and understand complex industrial machinery.

But as industries embrace Industry 4.0, the challenge for educators is clear:

how do you prepare students for digital factories using only physical tools?

To answer that question, Pignat partnered with 3dverse to explore a new frontier: immersive, real-time, cloud-native learning.

Together, they developed a proof of concept for a next-generation training platform — one that brings technical education into the digital era without losing the tactile precision and rigor of hands-on training.

A Strategic Collaboration: From Hardware to Hybrid Learning

This collaboration between Pignat and 3dverse wasn’t just about technology.

It was about rethinking how people learn technical processes — and how educators can scale that knowledge safely, efficiently, and globally.

The joint project set out to explore one simple but transformative idea:

Could the same detailed learning experience that once required a physical lab now happen entirely in 3D — accessible on any device, anywhere?

Why Pignat Chose 3dverse

Pignat selected 3dverse for a simple reason: speed and scalability.

With its cloud-native architecture and device-agnostic accessibility, 3dverse enabled Pignat to prototype and validate an immersive learning concept in less than 60 days — something that would have taken months using traditional software setups.

This rapid prototyping capability allowed Pignat to quickly test, iterate, and imagine how immersive training could integrate into its broader product and teaching ecosystem.

Project Goals: Bringing Digitalization to Technical Training

The proof of concept was designed around four clear objectives:

Digitize Practical Work Instructions

Transform existing training documents — previously available only as Word files — into interactive, 3D-based learning experiences.Explore Core 3dverse Capabilities

Evaluate real-time collaboration, immersive navigation, and accessibility in a training context.Familiarize Teams with Cloud-Native Platforms

Help Pignat’s educators and engineers experience firsthand how a real-time 3D platform functions and how it could integrate into their workflows.

Lay the Foundation for Digital Transformation

Initiate a strategic reflection on how digitalization could enhance Pignat’s core processes, from training to customer support and equipment lifecycle management.

Building the Prototype: A New Era of Digital Learning

The resulting prototype was an immersive 3D training platform accessible from any device — desktop, tablet, or VR headset.

Its goal: faithfully replicate how students interact with a real Pignat training system while introducing the interactivity and scalability of a digital twin.

Prototype Highlights

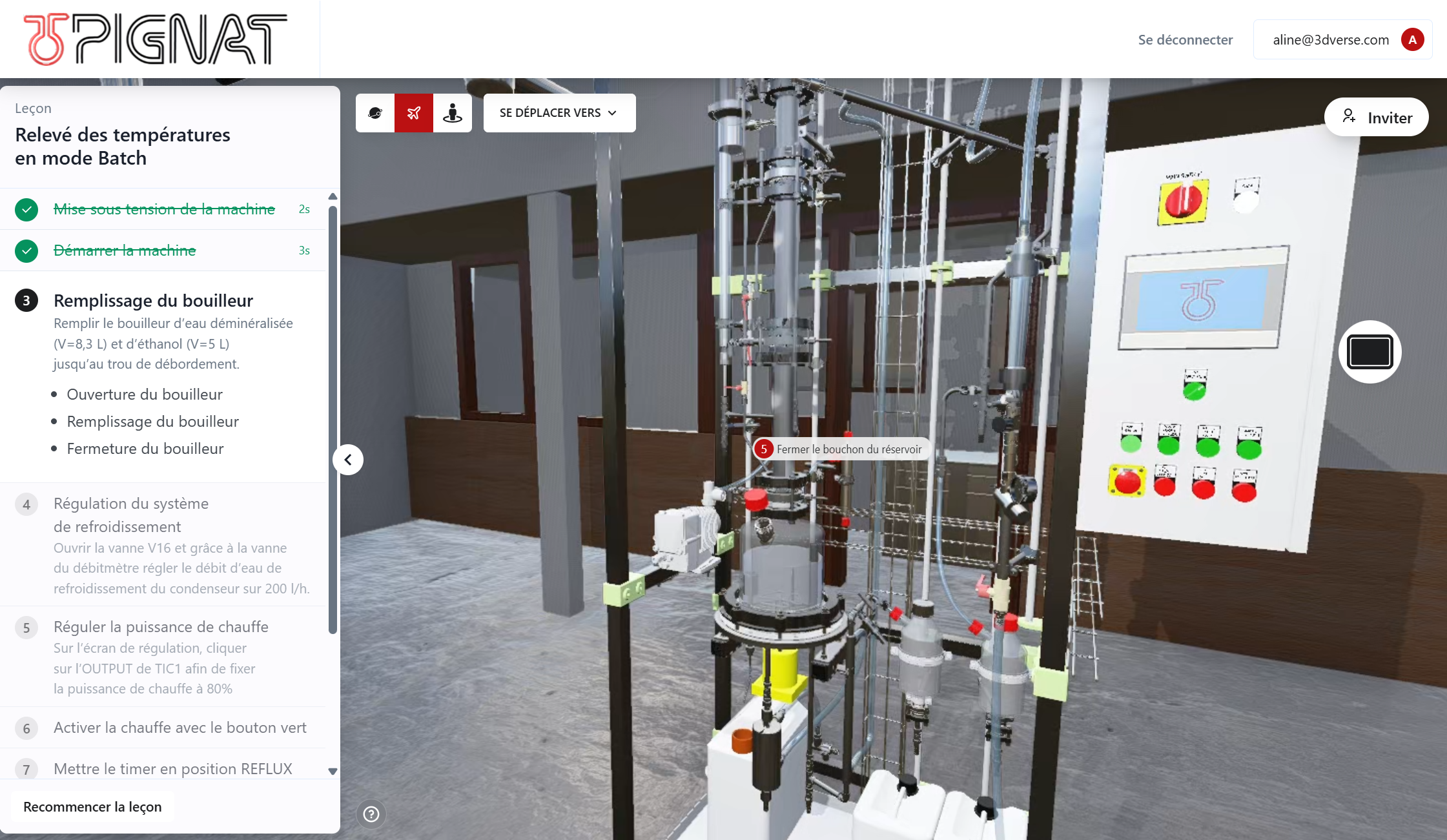

Immersive 3D Environment

A digital replica of a DVI 3000 machine and its surroundings allowed users to navigate freely, observe, and interact as if standing next to the real unit.Interactive Guide

Step-by-step operating procedures were embedded directly in the scene, providing users with contextual instructions instead of static PDFs.Temperature Reading Simulation

A functional control panel simulated sensor readings and real-time reactions, helping trainees visualize cause and effect through data.Virtual Control Interface

The system reproduced every button, lever, and input control of the physical equipment — letting users manipulate parameters safely and intuitively.Collaborative Learning

Multiple users could join the same session simultaneously, enabling group exercises, instructor-led demonstrations, and peer collaboration from anywhere.

Results: Validating the Power of Immersive Learning

The proof of concept succeeded in demonstrating that immersive, cloud-native training is both feasible and effective for industrial education.

By converting text-based work instructions into 3D simulations, learners could familiarize themselves with procedures before ever touching the physical equipment, improving confidence and reducing classroom training time.

The experiment validated key hypotheses:

Immersive environments enhance engagement and retention.

Training can be conducted safely and remotely.

Collaboration is possible in real time, without local software installation.

This early success positions Pignat to extend its teaching solutions into hybrid models — combining real-world equipment with digital twins to maximize both safety and accessibility.

A Strategic Step Toward Full Digitalization

This pilot marks a turning point for Pignat.

By validating the technical feasibility and pedagogical impact of immersive training, the company has laid the groundwork for a long-term digital roadmap.

It’s not just about digitizing lessons — it’s about modernizing how knowledge is shared, ensuring that industrial education keeps pace with industrial innovation.

The collaboration with 3dverse has given Pignat a scalable foundation for future projects, from advanced training systems to fully interactive digital twins of its educational units.

Beyond Training: 3dverse as a Platform for Digital Twins

While this proof of concept focused on training, the implications go further.

3dverse is not a content tool—it’s a real-time 3D operating system built to power digital twins across industries.

Its cloud-native architecture reduces development time, simplifies deployment, and minimizes operating costs.

From simulation and predictive maintenance to live process optimization, 3dverse enables organizations to bridge the gap between data, equipment, and decision-making—all in one shared spatial environment.

For Pignat, this project wasn’t just about creating a prototype. It was about stepping into the future of education and industrial collaboration.

Try the Demo