Digital TwinsBuilt for Real-World ImpactNot Just Prototypes.

Real-Time 3D. Cloud-Native. Secure.

Digital TwinsBuilt for Real-World ImpactNot Just Prototypes.Real-Time 3D. Cloud-Native. Secure.

Make Digital Twins Operational — at Scale

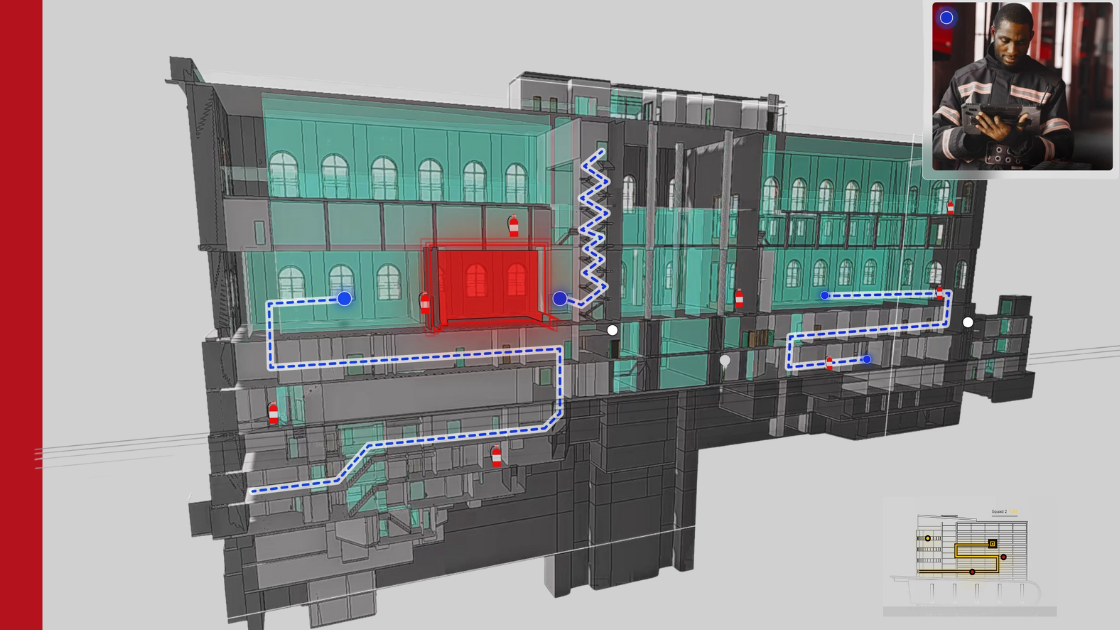

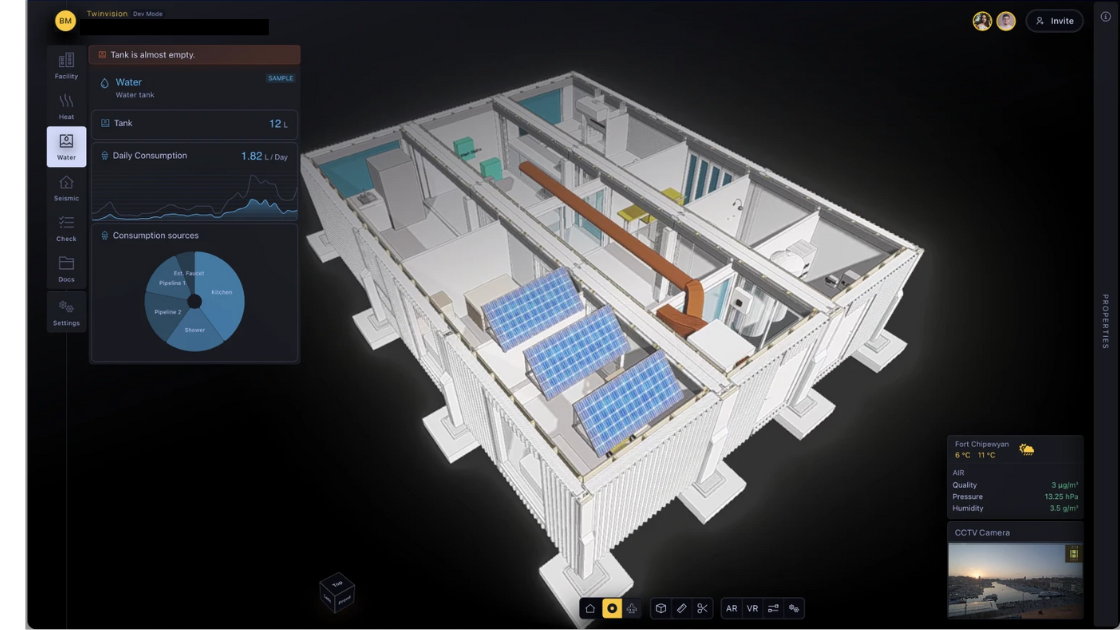

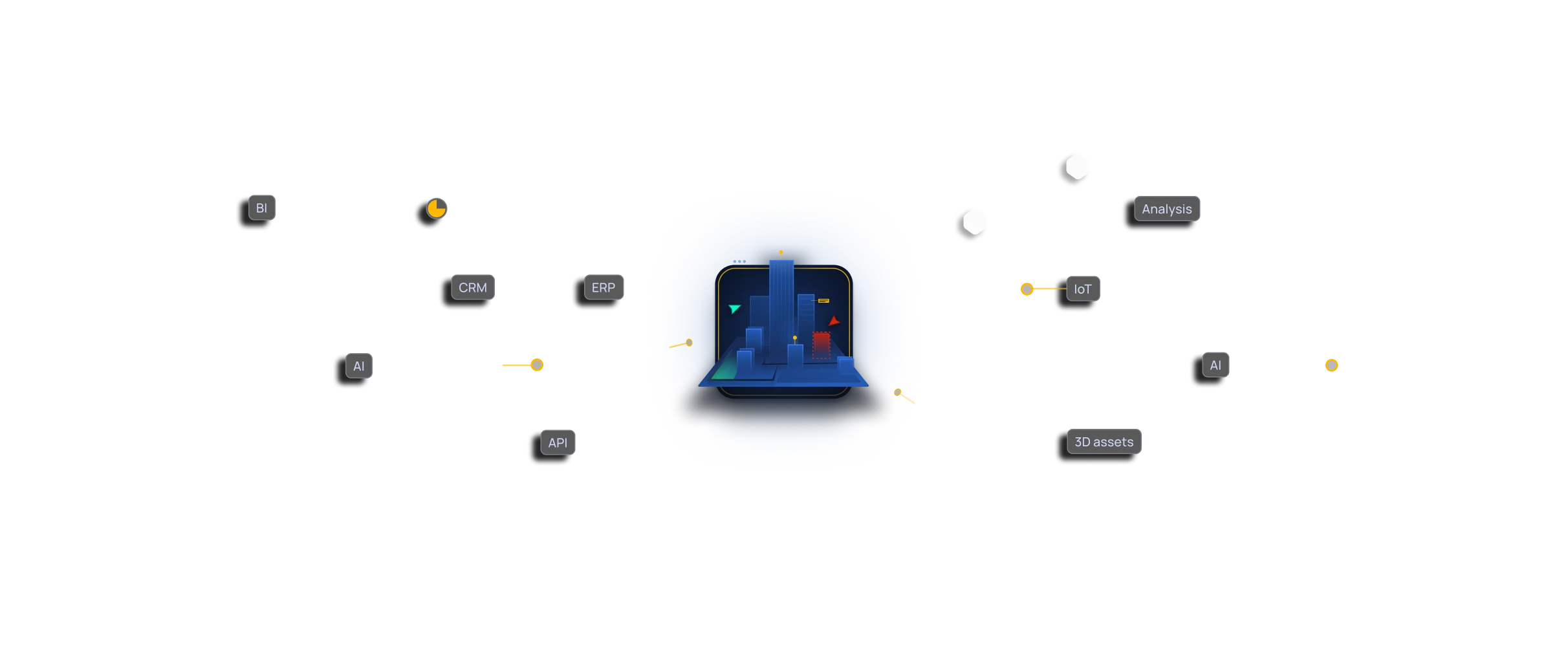

Digital twins built on 3dverse run entirely in the cloud and are accessible on any device — from desktop to mobile. By bringing together 3D assets, live operational data, and enterprise systems through standard industrial protocols and APIs (IoT, PLCs, AI services, ERP), organizations move beyond visualization to truly operational digital twins. The outcome is a single, shared source of truth teams rely on to monitor operations, simulate scenarios, collaborate across functions, and make faster, better-informed decisions — with measurable gains in uptime, efficiency, and planning.

The Engine Behind It All

With 3dverse, your organization builds and owns its digital twin on a cloud-native, real-time 3D operating system — while we handle the complexity of the underlying 3D infrastructure. Through REST APIs, SDKs, and the 3dverse Console, teams connect systems, synchronize data, and collaborate in real time, while cloud GPUs manage rendering and the platform handles scaling. Think Google Docs for 3D, built for industrial-grade digital twins.

20 - 30%1

Efficiency Gains

Up to 7×

Lower deployment costs

up to 90 %1

Faster Decision Making

1 McKinsey

With 3dverse, businesses achieve results beyond the limits of legacy software

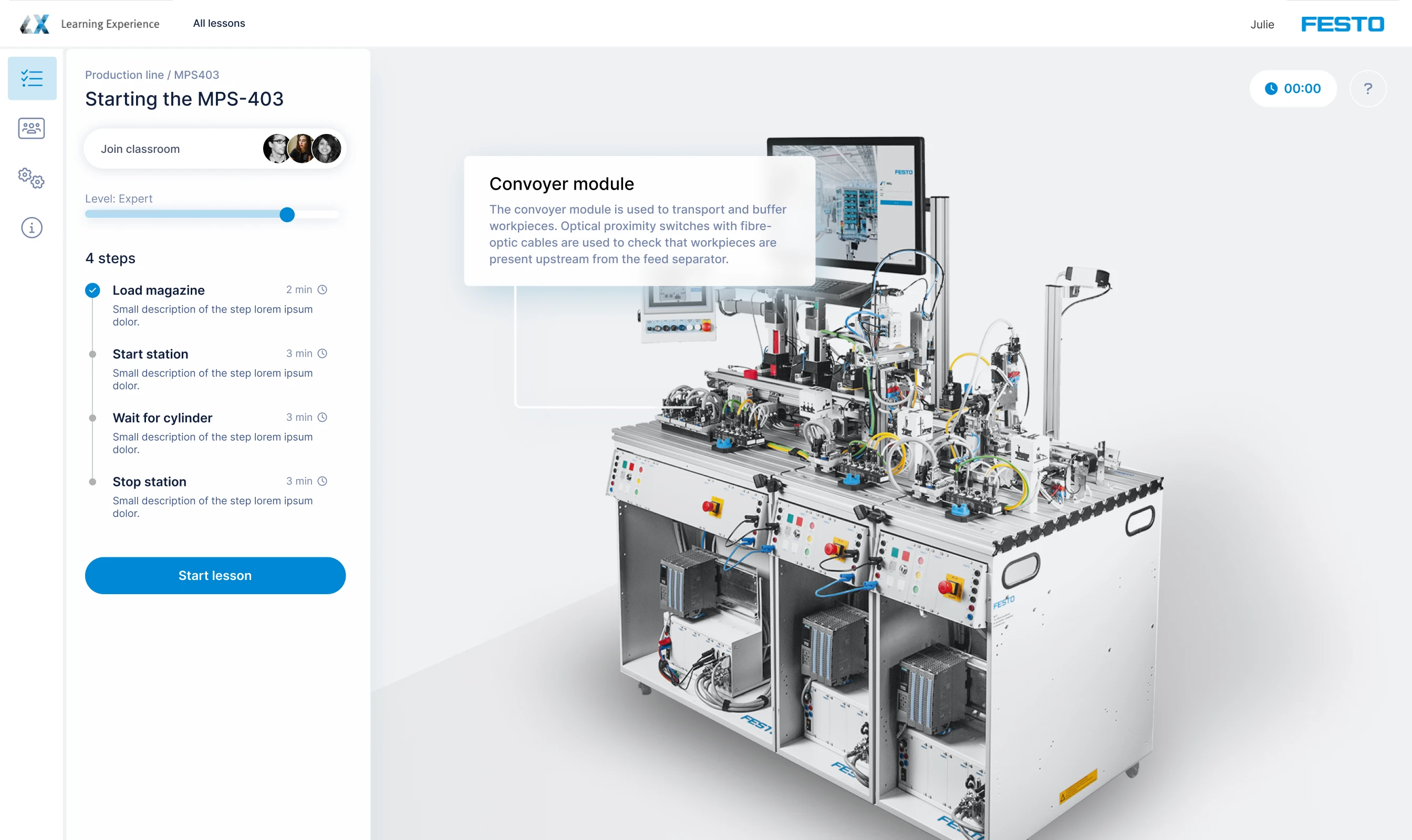

From the industrial metaverse to architecture, engineering, construction, smart cities, and beyond, we break the limits of traditional platforms to solve cross-industry challenges.

More than technology.

Your partner in digital twins.

With 3dverse, you can choose between full turnkey solutions or building directly with your team.

Built For You

Our team designs, builds, and scales projects on 3dverse, from rapid proofs of concept to global rollouts.

Contact us

Built By You

Your developers can use 3dverse to create and customize digital twins directly, supported by detailed documentation, SDKs, and responsive support.

Start building

Choose the path that fits your needs