Prototyping an Immersive Digital Learning Platform

To test the feasibility and effectiveness of digitizing practical work instructions, initially in Word format, for integration into an immersive 3D environment to improve learning and training.

Pignat and 3dverse: Building the Future of Immersive Technical Training

Accelerating Digital Transformation in Industrial Education

Pignat, a recognized leader in educational process engineering equipment, has taken a decisive step toward digital innovation by partnering with 3dverse. This collaboration marks Pignat’s entry into immersive learning, showcasing a forward-thinking approach to digital transformation in industrial training.

Together, the two companies have developed a prototype immersive training platform, unlocking new opportunities for interactive, accessible, and scalable education.

Why Pignat Chose 3dverse: A Cloud-Native OS for Rapid Prototyping

Pignat chose to collaborate with 3dverse for its ability to create prototypes quickly and efficiently. Thanks to 3dverse's cloud-native architecture and accessibility, Pignat was able to explore and validate the potential of an immersive learning platform in less than 60 days, surpassing the limitations of traditional solutions. For this first draft, 3dverse designed a prototype of an immersive digital learning platform accessible on any device (computers, tablets, VR headsets).

Project Goals: Introducing Digitalization in Technical Training

Proof of Concept: To test the feasibility and effectiveness of digitizing practical work instructions, initially in Word format, for integration into an immersive 3D environment to improve learning and training.

Feature Exploration: To evaluate 3dverse's key features, including real-time collaboration, immersive navigation, and accessibility, in the context of training.

Introduction to Digital: To familiarize Pignat with the possibilities of a cloud-native, real-time digital platform for training and beyond.

Preparing for Digitalization: To implement a strategic reflection on the future integration of digitalization into Pignat's processes.

Prototype Highlights: A New Era of Digital Technical Education

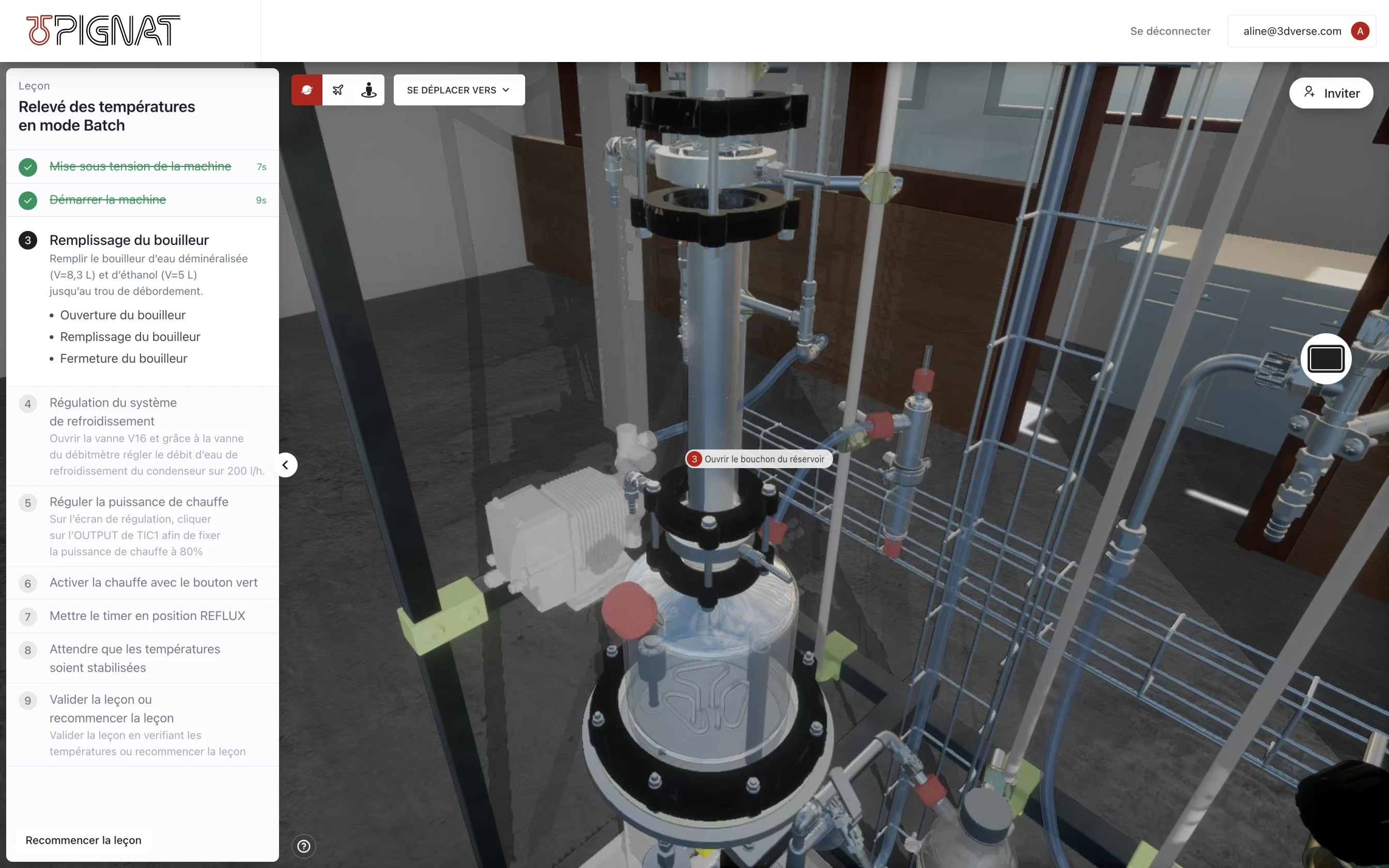

Training Module: An immersive 3D environment reproducing a DVI 3000 machine and its surroundings.

Interactive Guide: A step-by-step guide integrated into the platform to support users in learning operating procedures.

Temperature Reading Simulation: A functional replica of the control interface to manipulate virtual controls and observe real-time machine reactions.

Virtual Control Interface: A functional replica of the control interface to manipulate virtual controls and observe machine reactions in real time.

Collaborative Environment: The platform allows simultaneous interaction of multiple users, facilitating collaborative learning and expertise sharing.

Results: Validating the Power of Immersive Learning

The experience demonstrated the feasibility and effectiveness of the solution proposed by 3dverse. Through simulation, learners can safely familiarize themselves with the machine and its procedures, reducing the training time required on the equipment. This project paves the way for Pignat to explore new digital opportunities..

Conclusion: A Strategic Step Toward Full Digitalization

This pilot project with 3dverse marks a crucial step in Pignat's digital transformation. The validation of 3dverse's functionalities, particularly its ability to create an immersive training experience, confirms the platform's potential to support Pignat's transition to the digital age.

Beyond Training: 3dverse as an Operating System for Digital Twins

Beyond training, 3dverse is an operating system for digital twins. Its unique cloud architecture optimizes development time and reduces operating costs. With 3dverse, companies can create, manage, and operate digital twins (simulation, predictive maintenance, and process optimization). To learn more: 3dverse.com

Try the Demo